Description

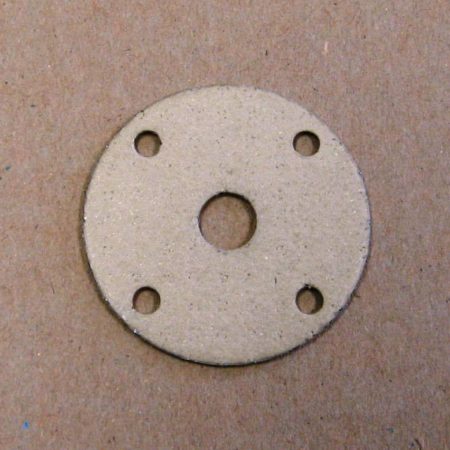

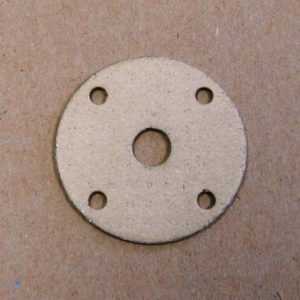

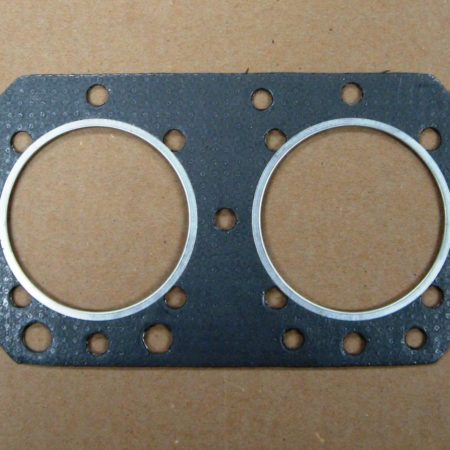

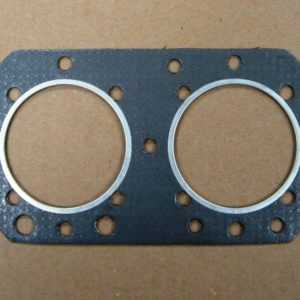

The Metal Tech Hi-Tex series features our specially designed starburst core tang technology. This robust metal core, available in carbon or stainless steel, provides optimum strength for the laminate in the most demanding applications. The starburst pattern provides 3-4 contact points around the tang and a columnar shape, providing excellent load retention and crush resistance. This technology is best used for high-temperature or high-load applications such as engine exhaust systems, where sufficient flange loading is available and load retention is required. Generally, the grades in this series are designed for applications such as exhaust manifolds, turbocharger applications, exhaust system gaskets, head gaskets, general industrial flange applications, etc. For more information about Hi-Tex, email sales@mtigasket.com!

Description

The Metal Tech Hi-Tex series features our specially designed starburst core tang technology. This robust metal core, available in carbon or stainless steel, provides optimum strength for the laminate in the most demanding applications. The starburst pattern provides 3-4 contact points around the tang and a columnar shape, providing excellent load retention and crush resistance.

This technology is best used for high-temperature or high-load applications such as engine exhaust systems, where sufficient flange loading is available and load retention is required. Generally, the grades in this series are designed for applications such as exhaust manifolds, turbocharger applications, exhaust system gaskets, head gaskets, general industrial flange applications, etc. For more information about Hi-Tex, email sales@mtigasket.com!

Graphite

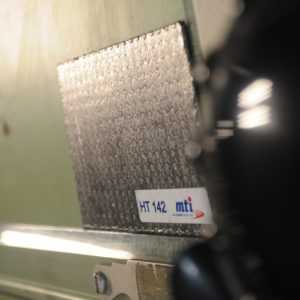

HT 142 – Economy graphite

Provides an economical solution where graphite gasketing is required. Learn more about

HT 142 – Economy graphite

Provides an economical solution where graphite gasketing is required. Learn more about

HT 142 – Economy graphite

Provides an economical solution where graphite gasketing is required. Learn more about

HT 195 – Globally sourced performance laminate

HT 195 – Globally sourced performance laminate

HT 195 – Globally sourced performance laminate

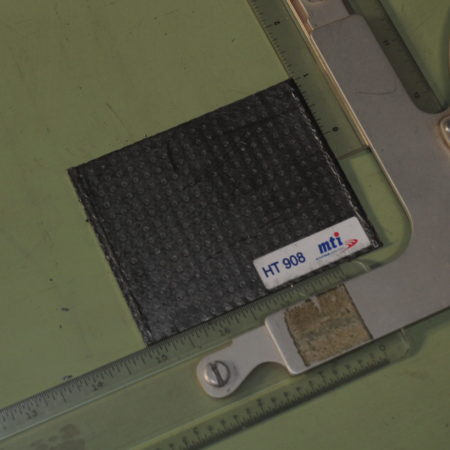

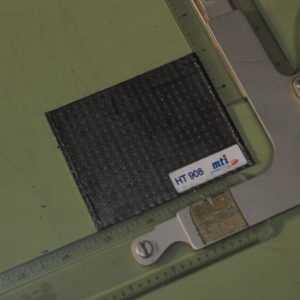

HT 908 – Proven domestic graphite

An excellent

HT 908 – Proven domestic graphite

An excellent

HT 908 – Proven domestic graphite

An excellent

HT 959 – Oxidation-resistant graphite

Recommended for OEM exhaust flange gasket applications and other

HT 959 – Oxidation-resistant graphite

Recommended for OEM exhaust flange gasket applications and other

HT 959 – Oxidation-resistant graphite

Recommended for OEM exhaust flange gasket applications and other

High-temperature fiber

HT 337 – Durable graphite/fiber blend

Universal material that can be used in a variety of applications including: sealing intake and exhaust, cylinder heads, high

HT 337 – Durable graphite/fiber blend

Universal material that can be used in a variety of applications including: sealing intake and exhaust, cylinder heads, high

HT 337 – Durable graphite/fiber blend

Universal material that can be used in a variety of applications including: sealing intake and exhaust, cylinder heads, high

HT 400 – Vermiculite fiber

Generally used for engine exhaust gaskets in various applications: manifolds, exhaust systems, EGR gaskets, diesel exhaust gaskets, turbochargers, etc. Oxidation threshold higher than graphite! Learn more about

HT 400 – Vermiculite fiber

Generally used for engine exhaust gaskets in various applications: manifolds, exhaust systems, EGR gaskets, diesel exhaust gaskets, turbochargers, etc. Oxidation threshold higher than graphite! Learn more about

HT 400 – Vermiculite fiber

Generally used for engine exhaust gaskets in various applications: manifolds, exhaust systems, EGR gaskets, diesel exhaust gaskets, turbochargers, etc. Oxidation threshold higher than graphite! Learn more about

HT 514 – Extreme temperature performance

Designed for extreme temperatures, withstands environments where other materials fail to survive, features a stainless steel core for

HT 514 – Extreme temperature performance

Designed for extreme temperatures, withstands environments where other materials fail to survive, features a stainless steel core for

HT 514 – Extreme temperature performance

Designed for extreme temperatures, withstands environments where other materials fail to survive, features a stainless steel core for

HT 654 – General purpose

Wide range of performance for economy exhaust applications. Learn more about

HT 654 – General purpose

Wide range of performance for economy exhaust applications. Learn more about

HT 654 – General purpose

Wide range of performance for economy exhaust applications. Learn more about