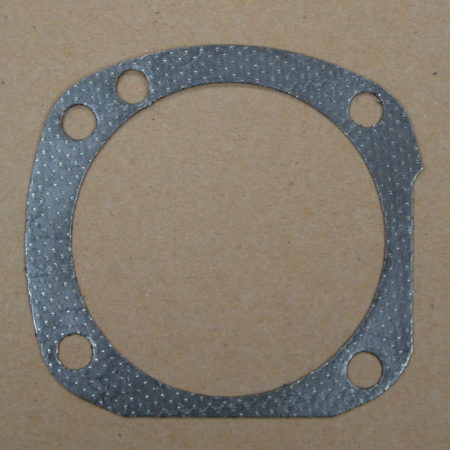

Description

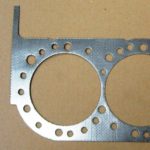

The Metal Tech Corseal series features a rectangular perforation pattern. This pattern has nearly twice the perforations per square inch as the starburst pattern, providing more contact points to grip the facing. It should be used for gaskets where land area is tight to be sure that there is a bond point in the cross section. This core also compresses at lower loads resulting in approximately 10% more compressibility over the same facing on the Hi-Tex core. This is advantageous when designing head gaskets or other critical fluid sealing gaskets. This core technology is commonly used for head gaskets, intake gaskets, engine fluid gaskets, cover gaskets, and general industrial flange gaskets. For more information about Corseal, email sales@mtigasket.com!

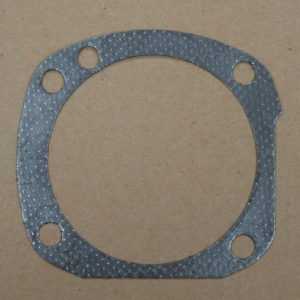

Description

The Metal Tech Corseal series features a rectangular perforation pattern. This pattern has nearly twice the perforations per square inch as the starburst pattern, providing more contact points to grip the facing. It should be used for gaskets where land area is tight to be sure that there is a bond point in the cross section.

This core also compresses at lower loads resulting in approximately 10% more compressibility over the same facing on the Hi-Tex core. This is advantageous when designing head gaskets or other critical fluid sealing gaskets. This core technology is commonly used for head gaskets, intake gaskets, engine fluid gaskets, cover gaskets, and general industrial flange gaskets. For more information about Corseal, email sales@mtigasket.com!

Graphite

CS 253 – Economy graphite

Provides an economical solution where graphite gasketing is required. Learn more about

CS 253 – Economy graphite

Provides an economical solution where graphite gasketing is required. Learn more about

CS 253 – Economy graphite

Provides an economical solution where graphite gasketing is required. Learn more about

CS 280 – Globally sourced performance laminate

CS 280 – Globally sourced performance laminate

Anti-oxidant graphite applied to rectangular-style, perforated steel core. OEM performance at an economical price. Learn more about CS 280!

CS 280 – Globally sourced performance laminate

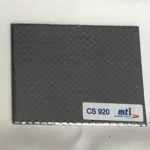

CS 920 – Proven domestic graphite

An excellent

CS 920 – Proven domestic graphite

An excellent

CS 920 – Proven domestic graphite

An excellent

CS 980 – Oxidation-resistant graphite

Recommended for OEM exhaust flange gasket applications, cylinder head gaskets, and other

CS 980 – Oxidation-resistant graphite

Recommended for OEM exhaust flange gasket applications, cylinder head gaskets, and other

CS 980 – Oxidation-resistant graphite

Recommended for OEM exhaust flange gasket applications, cylinder head gaskets, and other

High-temperature fiber

CS 365 – General purpose

CS 365 – General purpose

Wide range of performance while providing economical benefit for the user where costs are critical. Learn more about CS 365!

CS 365 – General purpose

Wide range of performance while providing economical benefit for the user where costs are critical. Learn more about CS 365!

CS 365 – General purpose

Wide range of performance while providing economical benefit for the user where costs are critical. Learn more about CS 365!

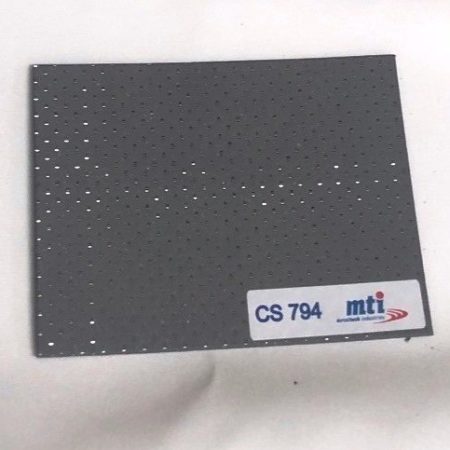

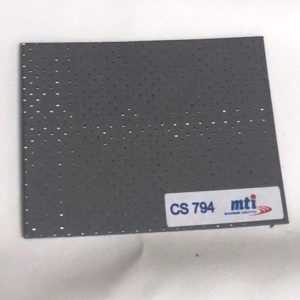

CS 794 – Performance fiber

CS 794 – Performance fiber

CS 794 – Performance fiber

CS 830 – Durable graphite blend

Universal material that can be used in a variety of applications including: sealing intake and exhaust, cylinder heads, high

CS 830 – Durable graphite blend

Universal material that can be used in a variety of applications including: sealing intake and exhaust, cylinder heads, high pressure/temperature engine ports, and high-performance turbocharger environments in engines from large diesels to lawn and garden uses. Learn more about CS 830!

CS 830 – Durable graphite blend

Universal material that can be used in a variety of applications including: sealing intake and exhaust, cylinder heads, high