Have you ever been doing research on a product and instead of being forced to read through a lot of mumbo-jumbo, you just want a nice eye chart with a little bit of explanation around it? Well, if you’re researching gasket materials and specifically want to see the differences between vermiculite and graphite, you’re in luck!

Have you ever been doing research on a product and instead of being forced to read through a lot of mumbo-jumbo, you just want a nice eye chart with a little bit of explanation around it? Well, if you’re researching gasket materials and specifically want to see the differences between vermiculite and graphite, you’re in luck!

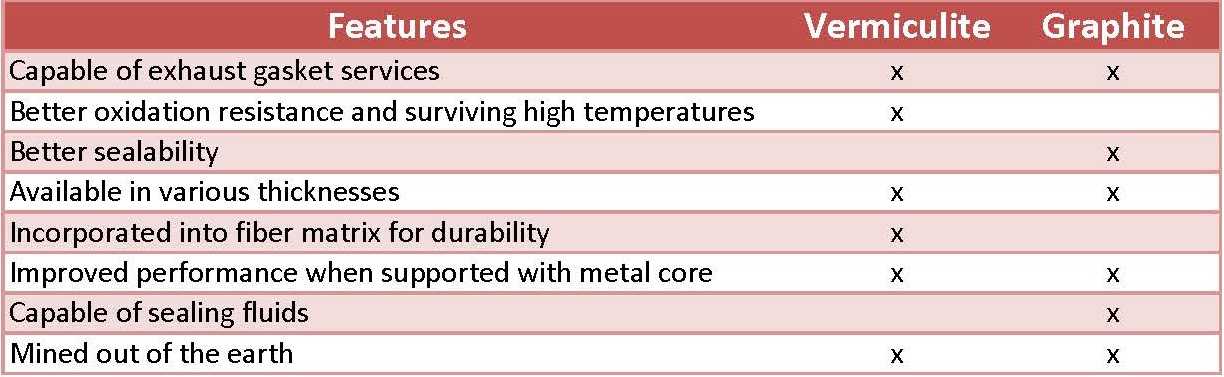

Each of these materials can hold its own, but they do have their specific strengths. Depending on your application, either vermiculite or graphite is going to be your best bet. Which one are you willing to put your money on?

What’s the Difference?

In general, when you are working with exhaust applications with high temps and signs of oxidation, you will want to look at a vermiculite product because it will resist oxidation more than graphite. If you are working with exhaust applications where sealabilty is critical and temperatures are not extreme, the graphites are going to meet your needs. If temperatures prove to be too much for the graphite, a vermiculite-based product is your next step.

Find The Right Material

This breakdown should get you pointed in the right direction on your quest to find the best gasket material for your application. You don’t need to do it alone, though. If you still aren’t sure what you need, talk with your trusted gasket material supplier. They can give you the pros and cons of all of their materials and help you narrow down the choices in preparation for your testing.

A gasket material that works is your ace in the hole! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

Have you ever been doing research on a product and instead of being forced to read through a lot of mumbo-jumbo, you just want a nice eye chart with a little bit of explanation around it? Well, if you’re researching gasket materials and specifically want to see the differences between vermiculite and graphite, you’re in luck!

Each of these materials can hold its own, but they do have their specific strengths. Depending on your application, either vermiculite or graphite is going to be your best bet. Which one are you willing to put your money on?

What’s the Difference?

In general, when you are working with exhaust applications with high temps and signs of oxidation, you will want to look at a vermiculite product because it will resist oxidation more than graphite. If you are working with exhaust applications where sealabilty is critical and temperatures are not extreme, the graphites are going to meet your needs. If temperatures prove to be too much for the graphite, a vermiculite-based product is your next step.

Find The Right Material

This breakdown should get you pointed in the right direction on your quest to find the best gasket material for your application. You don’t need to do it alone, though. If you still aren’t sure what you need, talk with your trusted gasket material supplier. They can give you the pros and cons of all of their materials and help you narrow down the choices in preparation for your testing.

A gasket material that works is your ace in the hole! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

Have you ever been doing research on a product and instead of being forced to read through a lot of mumbo-jumbo, you just want a nice eye chart with a little bit of explanation around it? Well, if you’re researching gasket materials and specifically want to see the differences between vermiculite and graphite, you’re in luck!

Each of these materials can hold its own, but they do have their specific strengths. Depending on your application, either vermiculite or graphite is going to be your best bet. Which one are you willing to put your money on?

What’s the Difference?

In general, when you are working with exhaust applications with high temps and signs of oxidation, you will want to look at a vermiculite product because it will resist oxidation more than graphite. If you are working with exhaust applications where sealabilty is critical and temperatures are not extreme, the graphites are going to meet your needs. If temperatures prove to be too much for the graphite, a vermiculite-based product is your next step.

Find The Right Material

This breakdown should get you pointed in the right direction on your quest to find the best gasket material for your application. You don’t need to do it alone, though. If you still aren’t sure what you need, talk with your trusted gasket material supplier. They can give you the pros and cons of all of their materials and help you narrow down the choices in preparation for your testing.

A gasket material that works is your ace in the hole! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.