If you ask half a dozen application engineers and gasket fabricators what they consider to be ‘high temperature’ in regards to their selection of gasket material, you’re likely to get a range of answers. You’ll also find that none of them are really wrong, since ‘high temperature’ is a relative term. So, how does one navigate the world of high-temperature gasket materials when the terminology is so ambiguous?

If you ask half a dozen application engineers and gasket fabricators what they consider to be ‘high temperature’ in regards to their selection of gasket material, you’re likely to get a range of answers. You’ll also find that none of them are really wrong, since ‘high temperature’ is a relative term. So, how does one navigate the world of high-temperature gasket materials when the terminology is so ambiguous?

One way is to gain an understanding of the variety of materials that are on the market so that you have a full appreciation of the strengths and weaknesses of certain materials as you move up in temperature. Also, it helps to at least have an idea of who the gasket material manufacturers are that manufacture material that survive higher temperatures than what you currently work with. If you are ever faced with issues related to temperature, you need to know who you can go to for assistance.

What Is High Temperature?

In MTI’s world, ‘high-temperature’ applications are generally anything that starts pushing into the 600°F – 800°F range and goes up from there (we have materials designed to survive temperature peaks of over 1900°F). The materials that we manufacture for the 300°F – 500°F range fall into a lower temperature classification in our catalog. However, some of you may only work with applications that reach 500°F, so that may be what you define as high temperature. Like we mentioned earlier, it is all relative.

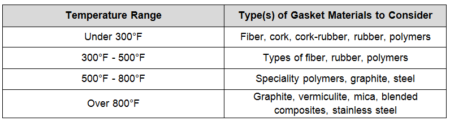

So, maybe focusing on terminology isn’t the best way to find a solution to your issues. We decided to put together a chart for you to review. Below we have listed temperature ranges and typical materials that are known to work best in those ranges. Please note that this is not an exhaustive list, and we have not tested this information (however, we can speak for our materials). All materials must be validated for use in your specific application. This is meant as a general guide for you to use when you talk with your trusted gasket material supplier.

Find Your Perfect Material

As you can see, temperature really does matter. The closer you creep towards 800°F, you must work with a different list of materials to survive in the applications. The good news is, what is out in the market does work. If you work with ‘high-temperature’ applications, or believe that temperature is an issue in what you believed to be a ‘low-temperature’ application, don’t hesitate to contact a gasket material supplier that specializes in materials that can survive the heat.

What is your definition of high temperature? If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

If you ask half a dozen application engineers and gasket fabricators what they consider to be ‘high temperature’ in regards to their selection of gasket material, you’re likely to get a range of answers. You’ll also find that none of them are really wrong, since ‘high temperature’ is a relative term. So, how does one navigate the world of high-temperature gasket materials when the terminology is so ambiguous?

One way is to gain an understanding of the variety of materials that are on the market so that you have a full appreciation of the strengths and weaknesses of certain materials as you move up in temperature. Also, it helps to at least have an idea of who the gasket material manufacturers are that manufacture material that survive higher temperatures than what you currently work with. If you are ever faced with issues related to temperature, you need to know who you can go to for assistance.

What Is High Temperature?

In MTI’s world, ‘high-temperature’ applications are generally anything that starts pushing into the 600°F – 800°F range and goes up from there (we have materials designed to survive temperature peaks of over 1900°F). The materials that we manufacture for the 300°F – 500°F range fall into a lower temperature classification in our catalog. However, some of you may only work with applications that reach 500°F, so that may be what you define as high temperature. Like we mentioned earlier, it is all relative.

So, maybe focusing on terminology isn’t the best way to find a solution to your issues. We decided to put together a chart for you to review. Below we have listed temperature ranges and typical materials that are known to work best in those ranges. Please note that this is not an exhaustive list, and we have not tested this information (however, we can speak for our materials). All materials must be validated for use in your specific application. This is meant as a general guide for you to use when you talk with your trusted gasket material supplier.

Find Your Perfect Material

As you can see, temperature really does matter. The closer you creep towards 800°F, you must work with a different list of materials to survive in the applications. The good news is, what is out in the market does work. If you work with ‘high-temperature’ applications, or believe that temperature is an issue in what you believed to be a ‘low-temperature’ application, don’t hesitate to contact a gasket material supplier that specializes in materials that can survive the heat.

What is your definition of high temperature? If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

If you ask half a dozen application engineers and gasket fabricators what they consider to be ‘high temperature’ in regards to their selection of gasket material, you’re likely to get a range of answers. You’ll also find that none of them are really wrong, since ‘high temperature’ is a relative term. So, how does one navigate the world of high-temperature gasket materials when the terminology is so ambiguous?

One way is to gain an understanding of the variety of materials that are on the market so that you have a full appreciation of the strengths and weaknesses of certain materials as you move up in temperature. Also, it helps to at least have an idea of who the gasket material manufacturers are that manufacture material that survive higher temperatures than what you currently work with. If you are ever faced with issues related to temperature, you need to know who you can go to for assistance.

What Is High Temperature?

In MTI’s world, ‘high-temperature’ applications are generally anything that starts pushing into the 600°F – 800°F range and goes up from there (we have materials designed to survive temperature peaks of over 1900°F). The materials that we manufacture for the 300°F – 500°F range fall into a lower temperature classification in our catalog. However, some of you may only work with applications that reach 500°F, so that may be what you define as high temperature. Like we mentioned earlier, it is all relative.

So, maybe focusing on terminology isn’t the best way to find a solution to your issues. We decided to put together a chart for you to review. Below we have listed temperature ranges and typical materials that are known to work best in those ranges. Please note that this is not an exhaustive list, and we have not tested this information (however, we can speak for our materials). All materials must be validated for use in your specific application. This is meant as a general guide for you to use when you talk with your trusted gasket material supplier.

Find Your Perfect Material

As you can see, temperature really does matter. The closer you creep towards 800°F, you must work with a different list of materials to survive in the applications. The good news is, what is out in the market does work. If you work with ‘high-temperature’ applications, or believe that temperature is an issue in what you believed to be a ‘low-temperature’ application, don’t hesitate to contact a gasket material supplier that specializes in materials that can survive the heat.

What is your definition of high temperature? If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.