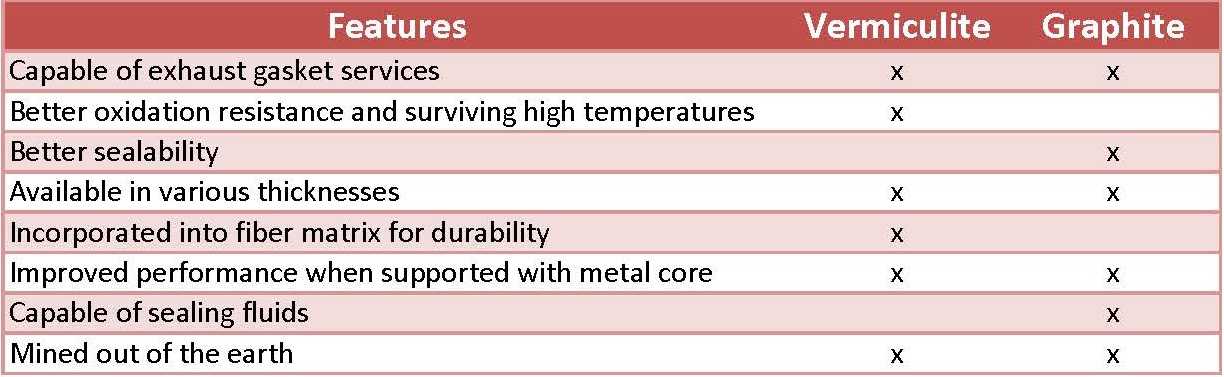

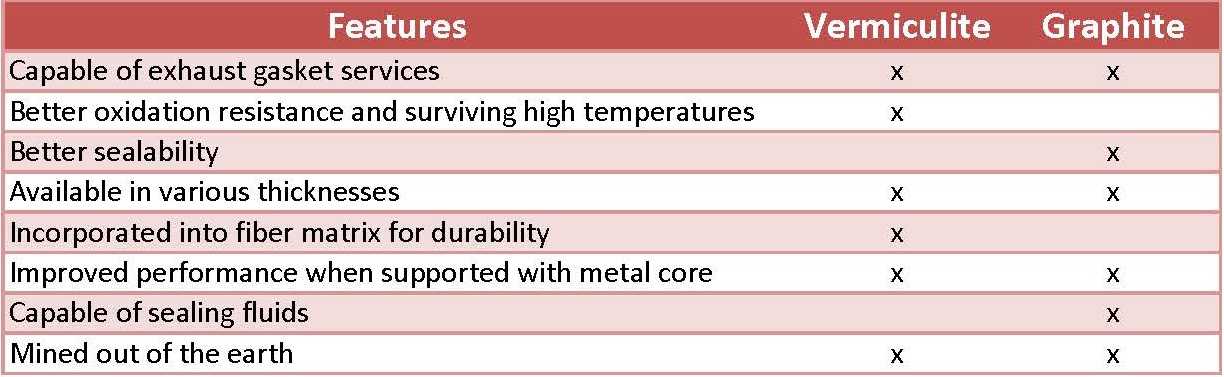

Either vermiculite or graphite is going to be your best bet?

Have you ever been doing research on a product and instead of being forced to read through a lot of mumbo-jumbo, you just want a nice eye chart with a little bit of explanation around it? Well, if you’re researching gasket materials and specifically want to see the differences between vermiculite and graphite, you’re in luck!

Each of these materials can hold its own, but they do have their specific strengths. Depending on your application, either vermiculite or graphite is going to be your best bet. Which one are you willing to put your money on?

What’s the Difference?

In general, when you are working with exhaust applications with high temps and signs of oxidation, you will want to look at a vermiculite product because it will resist oxidation more than graphite. If you are working with exhaust applications where sealabilty is critical and temperatures are not extreme, the graphites are going to meet your needs. If temperatures prove to be too much for the graphite, a vermiculite-based product is your next step.

Find The Right Material

This breakdown should get you pointed in the right direction on your quest to find the best gasket material for your application. You don’t need to do it alone, though. If you still aren’t sure what you need, talk with your trusted gasket material supplier. They can give you the pros and cons of all of their materials and help you narrow down the choices in preparation for your testing.

A gasket material that works is your ace in the hole! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

Solid Core vs Perforated Core Gasket Materials - What Are the Features of Each?

If you’re unfamiliar with the options and the materials used, composites can be very overwhelming. However, we’re here to help explain it as straightforwardly as possible. Basically, there are two main types of technologies used – perforated core (mechanically bonded) and solid core (chemically bonded). Ok…so what’s what, and what are the features of each?

Is There A Difference Between Gaskets & Seals?

Today we’re going to talk about gaskets and seals. These terms are generally used interchangeably. After all, gaskets seal a joint…so they’re the same, aren’t they? We want to get your thoughts on the matter...

Do I Need an O-ring or a Gasket?

How well do you understand the differences between O-rings and gaskets? Can you readily identify situations where each type of seal should be used? There are specific situations where each technology is needed because they are designed for completely different conditions. Today, we thought we’d dig a little deeper into gasket vs. O-ring.

Looking For A New Gasket Fabricator? Here Are 6 Questions To Ask.

Most of you probably have a handful of preferred fabricators that you use to cut your gaskets. What happens if you need to look for another fabricator for any reason? Do you know what questions should be asked to ensure you are finding the best fit for you?

5 Questions You Should Ask Your Supplier of Gasket Material

Your supplier of gasket material can be your best friend in the business or unfortunately, sometimes, your biggest headache. Deciding on a gasket material supplier is a big decision that will affect YOUR business – whether you are an OEM or a fabricator. Learning about the questions you should be asking may make that decision a little easier. As an experienced supplier of gasket material that has been asked a few questions over our 25 years, we thought it might be beneficial to list out some of the more important questions you may want to ask (and why you want to ask them).

Deciding Where to Buy Your Gasket Material? Here Are 6 Things to Think About.

There are a lot of factors that come into play when you make a decision. Depending on your situation, some may be more important to you than others at any given time. We compiled a list of things (in no particular order) that deserve some consideration when you are in the market for a new supplier.