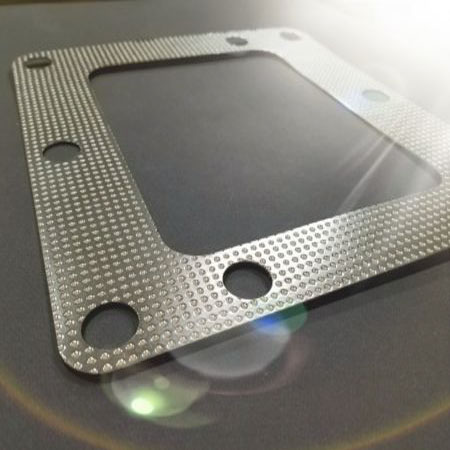

Reasons why load can be lost in a gasketed joint

Maintaining the desired load can be a challenge at times for a variety of reasons. Today we’re going to cover some of these reasons.

Before we get into it, we want to make sure all of our readers are on the same page and understand what we mean by ‘losing load’. Load is the amount of force (pressure) placed on flanges by applying torque (tightening the bolts) to create the proper seal with the gasket. When you ‘lose load’, your bolts do not retain the torque values applied to them and the gasket will no longer seal properly.

Losing Load

Here are a couple of reasons why you could be losing load, which may help you troubleshoot any issues.

1. Material has creep/relaxation.

Most compressible materials have some level of this which should be considered in the assembly.

2. Improper material selection

Materials exhibit different characteristics in assembled conditions. Be sure to understand the parameters to select the proper choice.

3. Insufficient load

Bolts are not torqued sufficiently.

4. Bolt incorrect

Bolts may be undersized or an improper grade for the load required.

5. Environmental exposure or thermal cycles

They can cause materials and hardware to lose load due to compression/recovery, creep/relaxation, bolt stretch/yield, etc.

Find Something That Works

The inability to achieve a proper seal due to loading issues can be a very frustrating issue to resolve. Using some of the information provided above can be a good starting point for you to resolve any of these issues. If troubleshooting seems to point back to a poor gasket material selection or a design flaw that cannot be fixed, talk to your trusted gasket material supplier. They should be able to offer a few suggestions on materials that may be better suited for your application.

What is the root cause of most of your loading issues? If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

What Is Bolt Load, and Why Do I Care?

This week, we’re going to talk about bolt load. You may also have heard the terms: torque load, flange load, or compressive force, which all refer to the same thing. Bolt load is something to keep in mind when you are designing your joint and selecting your gasket material. Without knowing or paying attention to it, you may be setting yourself up for an insufficient load situation…and a problem...

Re-torque?!? We don't need to re-torque! Or do we??

Do you understand when and why a re-torque would be needed to maintain an optimal seal in your joint? Is a re-torque ever not necessary? All of these burning questions and more are addressed in this week’s post.

What Is Torque Retention, and Why Do I Care?

This week, we’re going to talk about torque retention (or torque loss, depending on your particular viewpoint) and how it affects your gasket performance. Torque retention is related to many of the topics previously discussed, but we thought we’d take a closer look at it specifically.

What Is Compressibility & Recovery, and Why Do I Care?

This week, we’re going to talk about compressibility and recovery. These are two of the most important properties in selecting a gasket material, and ones you definitely need to pay attention to. Having a material with the right compressibility and recovery for your application makes all the difference in the performance of the application. Learn more!

What Is Creep Relaxation, and Why Do I Care?

This week, we’re going to talk about creep relaxation in gaskets and gasket material. This is something that will happen to some extent in most gasket materials. How much or how little of this you see depends on your gasket material selection and the application itself. It is important to have an understanding of creep relaxation and how it relates to a particular material.

6 Ways to Ensure You Have a Tight Seal in Your Gasketed Joint

The lack of a tight seal in a gasketed joint is a ticking time bomb. The good news (for those of you that love troubleshooting) is that there are a variety of things that can contribute to the problem. We put together a short list of things that you should consider when it comes time to design or troubleshoot your gasketed joint.

The Great Gasket Debate: To Reuse or Not To Reuse

As an expert resource that knows gasket material inside and out, we’re going to break down some of the arguments for and against reusing, and what you need to consider when making that decision for your application. And maybe…there is a time or two that it really might be ok to reuse one.