Have you ever been faced with the decision of whether your gaskets are going to need a ring or not?

Maybe you’re still in the design stage and are merely asking the question, or you may be experiencing test failures and you’re wondering if a ring is going to be a solution for you. Beyoncé once famously told us, “If you like it, then you should have put a ring on it.” Fortunately, your decision is going to be based on data and not emotion, and it’s also comparatively much less expensive and (hopefully) not a life-changing decision for you.

Don’t worry…we’re here to help guide you in your decision-making process. Here is a list of reasons why you might find a need to put a flange ring on your gasket.

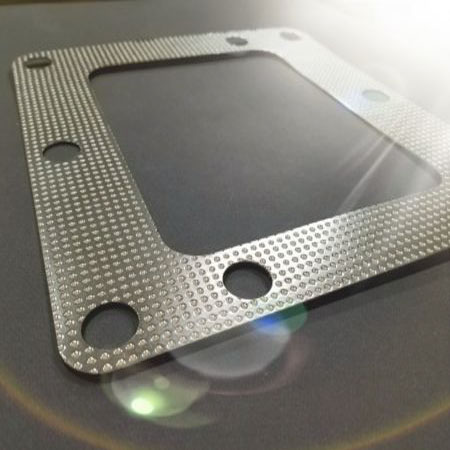

Why You May Need A Flange Ring

- There is internal pressure (such as combustion pressure) that needs to be contained.

- The gasket material needs to be protected from the internal fluid or pressure or high-temp exposure that might degrade it over time.

- There are loading issues with the bolting such that a metal-to-metal loading will better retain bolt torque values.

- A burn path needs to be avoided. The ring will provide a barrier to this potential for a burn path to work its way through the gasket body to create a leak path.

In case you’re now wondering, here are a few examples of gaskets that use rings: cylinder head gaskets, turbo system exhaust gaskets, high-pressure fluid port gaskets, etc.

It’s Pretty Simple

The data doesn’t lie. If you are seeing (or believe you will see) any of these factors in your design, your best bet is to redesign/design your gasket with a ring. Although it will add cost to your design, it is going to ensure performance – and that is what we all want. Don’t be afraid of added cost up front…think of all the money you’re going to save later when your application doesn’t fail.

If you have any questions about your design and what you might be seeing, please don’t hesitate to ask!

For those of you familiar with Beyoncé’s song “Single Ladies”, we apologize for putting that song into your head the rest of the day. We’ve been singing it to ourselves since we wrote this! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

Do I Need an O-ring or a Gasket?

How well do you understand the differences between O-rings and gaskets? Can you readily identify situations where each type of seal should be used? There are specific situations where each technology is needed because they are designed for completely different conditions. Today, we thought we’d dig a little deeper into gasket vs. O-ring.

Re-torque?!? We don't need to re-torque! Or do we??

Do you understand when and why a re-torque would be needed to maintain an optimal seal in your joint? Is a re-torque ever not necessary? All of these burning questions and more are addressed in this week’s post.

Is There A Fluid Leak In Your Joint? Here’s What You Need To Know.

Today, we’re going to take a deep dive into some of the potential causes of your fluid leak. As you’ll see, you can’t always just blame your gasket. Here are a few reasons why your joint may be leaking fluid, and what you can do about it.

4 Questions to Ask When You Need to Seal Fluids

Whether you are new to the fluid sealing market or you’ve been immersed in it for years, there are some considerations that must be made when you need to seal fluids. Some may be made subconsciously, but others sometimes require much debate and testing. This week, we thought we’d lay out the important questions that need to be asked (and why) when you are faced with a joint that requires fluid to be sealed.

Uneven Temperature Exposure – Is There A Solution?

We have recently been looking at applications that have uneven temperature exposure around the perimeter of gaskets. In some cases, one side sees more heat than the other. From the material manufacturing side, there are a number of things we can do...

Losing Load in a Gasketed Joint? Here’s What You Can Do About It.

There are many reasons why load can be lost in a gasketed joint. Maintaining the desired load can be a challenge at times for a variety of reasons. Today we’re going to cover some of these reasons.

What Is Bolt Load, and Why Do I Care?

This week, we’re going to talk about bolt load. You may also have heard the terms: torque load, flange load, or compressive force, which all refer to the same thing. Bolt load is something to keep in mind when you are designing your joint and selecting your gasket material. Without knowing or paying attention to it, you may be setting yourself up for an insufficient load situation…and a problem...